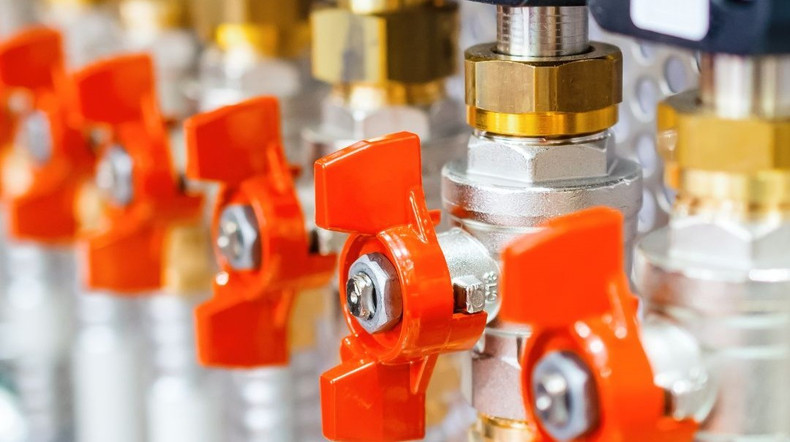

Valves are important components in fluid control systems, playing a crucial role in regulating the flow, pressure, and direction of liquids, gasses, and slurries. From industrial processes to household plumbing systems, valves are all-over and diverse, with various types designed to meet specific application requirements. In this comprehensive guide, we'll delve into the world of valves, exploring their different types, functions, and applications.

Gate Valves:

Gate valves are among the most common types of valves, characterized by a flat closure element (gate) that slides perpendicular to the flow direction to control the fluid flow. They provide excellent shutoff capability but are not suitable for regulating flow, as they are typically fully open or fully closed.

Ball Valves:

Ball valves feature a spherical closure element (ball) with a hole that aligns with the flow path when open and blocks it when closed. They offer quick, reliable shutoff and are ideal for applications requiring frequent operation or throttling.

Butterfly Valves:

Butterfly valves employ a circular disc (butterfly) mounted on a shaft to control the flow. When the disc is parallel to the flow direction, the valve is fully open, allowing unrestricted flow. Rotating the disc perpendicular to the flow direction closes the valve, providing shutoff.

Check Valves:

Check valves, also known as non-return or one-way valves, allow fluid flow in one direction while preventing reverse flow. They are commonly used to maintain system integrity, prevent backflow, and protect equipment from damage.

Globe Valves:

Globe valves feature a globe-shaped closure element (plug) that moves perpendicular to the flow path to regulate fluid flow. They offer precise control over flow rates and are commonly used in applications requiring throttling or fine-tuning of flow.

Pressure Relief Valves:

Pressure relief valves automatically release excess pressure from a system to prevent damage or catastrophic failure. They open when the pressure exceeds a predetermined threshold and close when the pressure returns to a safe level.

Control Valves:

Control valves regulate fluid flow by modulating the position of a closure element (plug, ball, or disc) in response to signals from a control system. They are widely used in process industries to maintain desired process variables such as flow rate, pressure, and temperature.

Conclusion:

Valves are essential components in fluid control systems, enabling precise regulation of flow, pressure, and direction. By understanding the different types of valves and their applications, engineers and operators can select the most suitable valve for their specific needs, ensuring optimal performance and system integrity.

Whether it's gate valves for on/off service, ball valves for quick shutoff, or control valves for precise flow control, the diverse range of valves available caters to a wide range of industrial, commercial, and residential applications.

For more information on valves and their applications, consult with our experts. We're here to help you find the right valve solution for your fluid control needs.